YOUR POSITION: HOME > Information

Edit:Zongxiang Heavy Industry--Ethan Date:2019-06-24 15:38:15

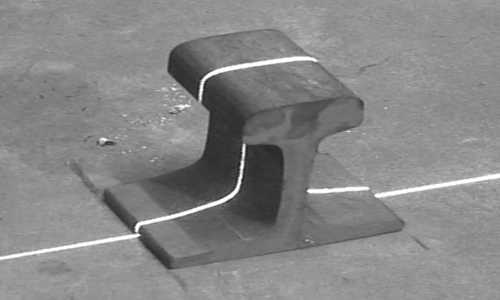

The control of orbital welding deformation depends on the type, length and fixing of the rail and the ambient temperature, use copper pad and carbon steel plate to pad the rail end 30~40mm, use the bolts and presssure plate joints that have been made, tighten the nuts to fix the rails on the rail beam, and set at least 4 fixing points near each rail joint.

After

welding the bottom of the rail, loosen the pressure plate, reduce the padded

portion of the rail end to 20mm, and then tighten the pressure plate nut. When welding

the waist portion of the rail, gradually lower the mat height, when the rail

waist portion is welded, the mat should be removed and the rail press plate

should be loosened, at this time, there should be a small upturn value at the

rail joint, during the process of applying the rail head, decide whether to

retighten the nut nut according to the straightness of the rail recovery.

The track has won the favor of users in the development of the company, in order to make the locomotive vehicle pass smoothly and safety, the track must be leveled and can bear the weight above, this requires us to pay attention to material selection and attention during processing method. Under the power of train operation, its various components must have sufficient strength and stability to allow the train to run smoothly and uninterrupted according to the specified high speed.

Email: zxsteel@zxsteelgroup.com

Whatsapp: +86 18236766038

Online Chat

To top